Design Tips

Get quick advice on creating plastic, metal, and elastomeric parts for 3D printing, CNC machining, and injection molding. Designing with manufacturability in mind can accelerate production time and reduce production costs.

| Adding Strength |

Insert Molding |

Multi-Cavity Molds |

| Bosses |

Knit Lines |

Multipart Assemblies |

| Cams and Side-Actions |

Lenses |

Overmolding |

| Channels |

Leveraging Low-Volume Molding |

Parting Lines |

| Clips |

Living Hinges |

Radii |

| Complex Parts |

LSR Molding |

Reducing Molding Costs |

| Core and Cavity |

Mating Parts |

Ribs |

| Cosmetic Defects |

Metal Safe Molds |

Shut-offs |

| Designing for Moldability |

Mistakes to Avoid When Designing Molded Parts |

Side-Actions |

| Draft |

Mold Modifications |

Surface Finish |

| Ejector Pins |

Mold Textures |

Text |

| Gates |

Molded Threads |

Undercuts: Fundamentals |

| |

Wall Thickness |

Undercuts: Complexities |

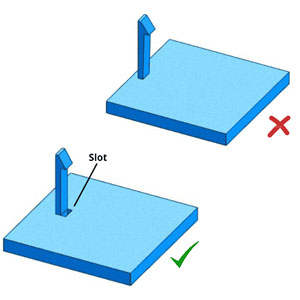

Undercuts

-

| Tips |

Benefit |

| To have a slot on undercut features |

1.simplify mold structure

2.reduceing cost

3.durable

|

-

Draft

-

| VERTICAL FACES |

0.5° |

| MOST SITUATIONS |

2° |

| MINIMUM FOR SHUT OFF |

3°

|

| MINIMUM FOR LIGHT TEXTURE (PM-T1) |

3°

|

| MINIMUM FOR LIGHT TEXTURE (PM-T2) |

5°+

|

-

Wall Thickness

-

| MATERIAL |

RECOMMENDED WALL THICKNESS |

| ABS |

1.143mm - 3.556mm

|

| Nylon |

0.762mm - 2.921mm

|

| PC |

1.016mm - 3.81mm

|

| PE |

0.762mm - 5.08mm

|

| PP |

0.635mm - 3.81mm

|

| PS |

0.889mm - 3.81mm

|

Overmolding Material Bonding

Chemical bonding between overmolded materials is possible, but material compatibility should be considered in order to achieve desired bond strength. Incorporation of an adequate mechanical bond is strongly recommended if bonding is critical to your application. An undercut is a good example of a mechanical bond

| |

Substrate Material |

| Overmold Material |

ABS Lustran |

ABS/PC CYCOLOY C2950-111 |

PC Lexan

940-701 |

PBT Valox

357-1001 |

PP Profax 6323 |

TPU - Texin

983-000000 |

C |

C |

C |

C |

M |

TPV - Santoprene

101-87 |

M |

M |

M |

M |

C |

| TPC - Hytrel 3078 |

C |

C |

C |

C |

M |

TPE-Versaflex OM

1060X-1 |

C |

C |

C |

M |

M |

( M = mechanical bond (recommended) C = chemical bond )