Leave A Message

Would you please leave us a message when you need customized plastic part or plastic mold,we will respond to you within 24 hours. Thank you for your time!

01

01 Need to know the product technical drawing (PDF & STEP / IGS / STP / SLDPRT / X_T), quantity, material, finish before quoting. Get a quote within 24 hours.

02

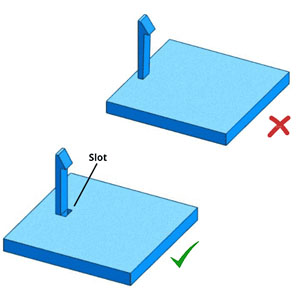

02 Part requirement details and manufacturability (DFM) analysis, communication and confirmation After you confirmed our offer,

03

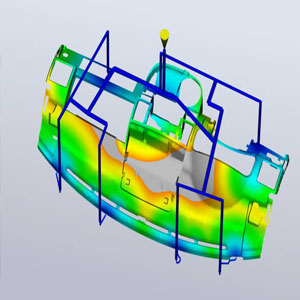

03 Kick off Mold design/Mold manufacturing,we will make samples for your reference before batch production.

04

04 Confirm the batch order details (quantity, lead time, packing info), then arrange the shipment.